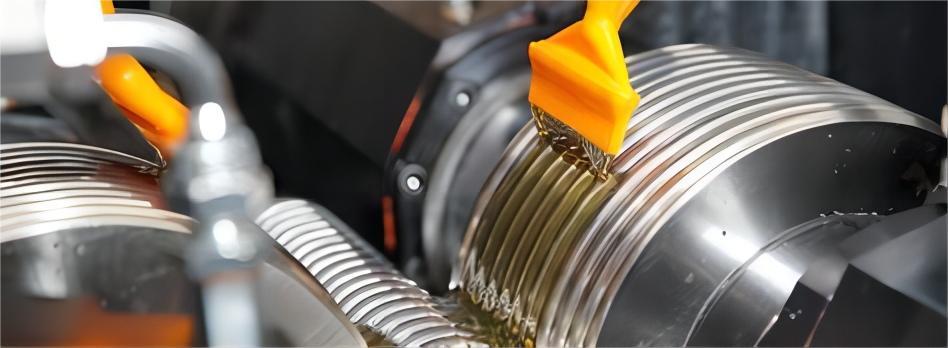

The processing method using SFD forming and rolling dies involves inducing plastic deformation in workpieces to produce threads. Thread rolling is typically performed on a rolling machine or an automatic lathe equipped with an automatic opening and closing thread rolling head, making it suitable for mass production of external threads on standard fasteners and other threaded connections.

Thread rolling methods vary based on the forming technique and the shape of the thread rolling die, which can be categorized into rolling and grinding methods, and further into convex and non-convex shapes.

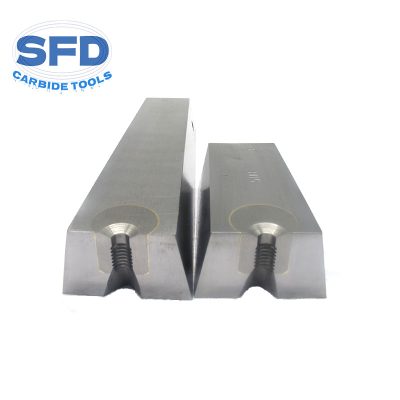

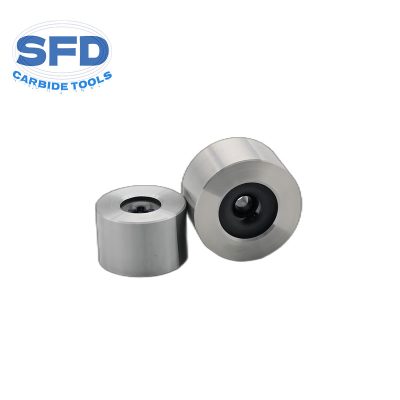

Before heat treatment, the thread profile of the rolling die is cold-rolled using a rolling column. Post heat treatment, the thread profile is not further processed, with a surface hardness requirement of 58-62HRC.

The process flow for rolling wire dies is as follows: cutting → forging → annealing → machining (including threading) → quenching, tempering → grinding both end faces → grinding inner holes and keyways → finished product inspection.

The heat treatment process for grinding and rolling wire dies includes: preheating → heating → cooling → tempering → cleaning → cold treatment (as required) → tempering → cleaning → hardness inspection → surface treatment → appearance inspection.

The advantages of SFD thread rolling dies including:

- Surface roughness is less than that of turning, milling, and grinding.

- The surface of the thread after rolling can improve strength and hardness due to cold work hardening.

- High material utilization rate.

- Productivity is significantly higher compared to cutting, and it is easy to achieve automation.

- The lifespan of rolling molds is very long.

However, rolling threads require the hardness of the workpiece material not to exceed HRC40, high precision for the dimensions of the blank, and high precision and hardness for the rolling molds, making mold manufacturing challenging. It is not suitable for rolling threads with asymmetric tooth shapes.