SFD Diamond Grinding Wheel is made of synthetic diamond as the main abrasive, and bond types can be metal, resin, electroplated, brazed, or vitrified; It has high hardness, high strength, and strong grinding ability. It is used for grinding high and hard alloys, and non-metallic materials, cutting hard and brittle hard alloys, non-metallic minerals, and so on, such as cemented carbide, ceramics, agate, optical glass, semiconductor materials, wear-resistant cast iron, stone, and other high-hard and brittle materials and special materials processing.

Application:

SFD Grinding carbide-tipped and inserted toolings like end mills, saws, reamers, and cutters, nail spare parts and cutters, grinding precision operations on rolls, carbide dies, and carbide wear parts, precision finishing on tungsten carbide, ceramics, and ceramic thermal spray coatings, slot grinding, double-disc grinding, fine grinding, tool grinding, center-less grinding, OD grinding, and surface grinding.

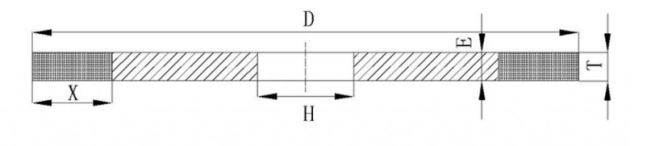

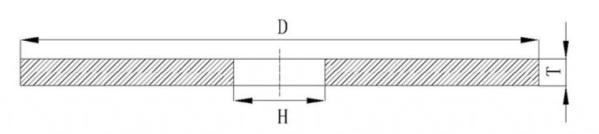

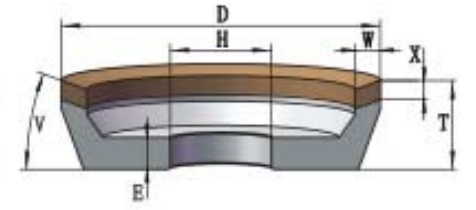

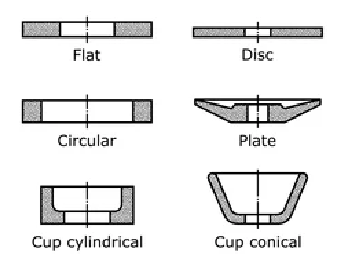

Our standard sizes and drawings are as follows: