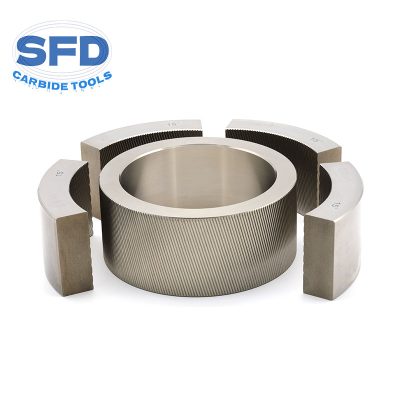

Our factory has been producing carbide roll blanks for up to 15 years, and has rich experience in various production processes. The quality of the cold rolling roll blanks produced is among the top in the industry. For cold carbide roller, we generally use 100% raw materials from Xiamen Golden Egret (GESAC) , which is the best quality domestic brand.

Why choose SFD wire tools?

- One stop solution for steel wire industry: SFD has evolved from offering a single product line of carbide roller to providing a complete design for steel wire industry. We do not only offer expert services and one-stop procurement solutions, but also share market information and strategic partners to clients which agree to our culture and value.

- Quality control systems: The production and processing of raw materials are subject to strict quality control systems. Each set of exported carbide cold roller is engraved with a unique internal traceability code by SFD, ensuring good quality assurance and best after sales service.

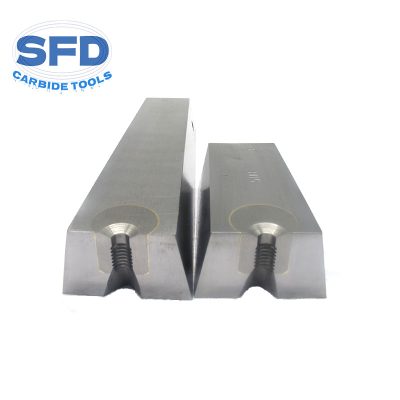

- Customized solutions: According to the customized standards for building steel bars in each country, the accuracy of the ribs on the steel bars produced by the rolling mill can reach 0.01-0.02mm.

- Technological innovation: Three-dimensional carbide rolls are the fist product of SFD, we are committed to continuous product innovation and process improvement to meet the new standards in the rebar industry, enhancing market competitiveness for end user.

FAQ:

- 1. What’s your standard size?

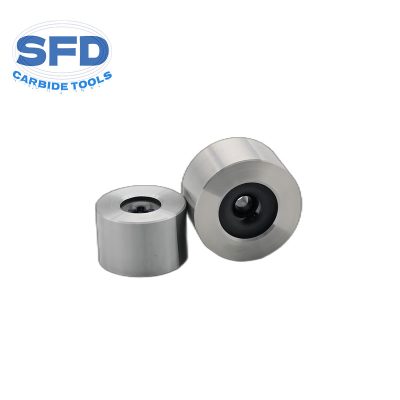

Our standard sizes are as below:

Ø76 x ø52 x 10 mm Ø89 x ø65 x 15 mm

Ø 123 x Ø 82 x 15/20mm Ø 125 x Ø 82 x 15/20mm

Ø 140 x Ø 90 x 15/20mm Ø 150 x Ø 90 x 15/20mm

Ø 160 x Ø 90 x 15/20mm Ø 220 x Ø130x 15/20mm

- 2.How do I choose the roll type?

Check the sequence of tungsten carbide roll in attachment, is the roll used for ribbed steel wire or smooth steel wire? we will choose the detailed type as per the final wire size.

- 3.Which carbide grade should I use?

It is decided by the rolling speed. YG15 is recommend for rolling machine less than 8m/s, YGH30 is recommend for rolling machine over 8m/s.

- 4.Can you offer repair service?

Regrinding service are acceptable, the shipping cost, tax and custom duty should be on your account, please contact us for further details.