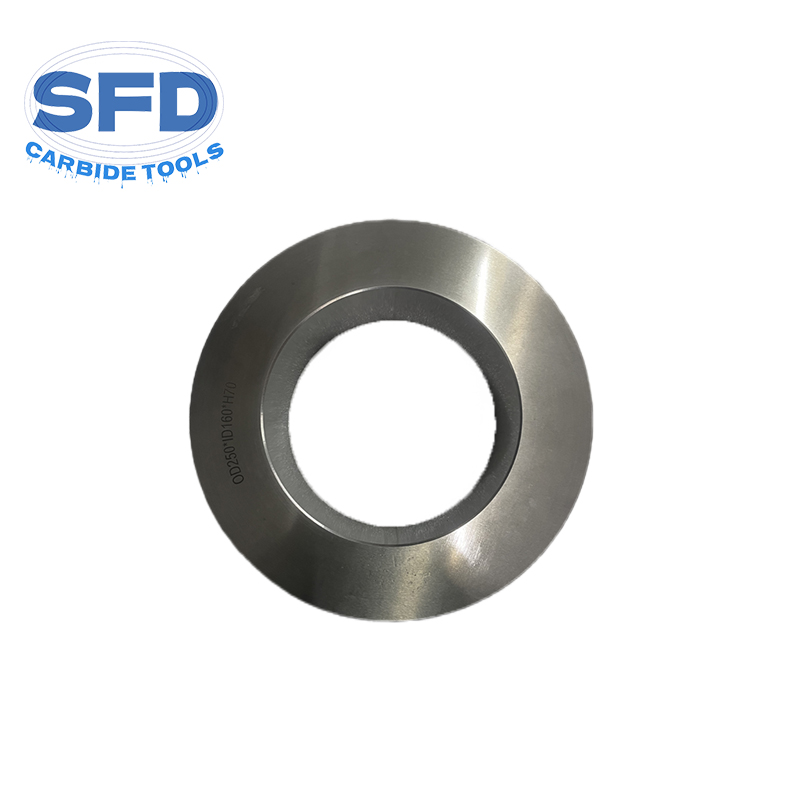

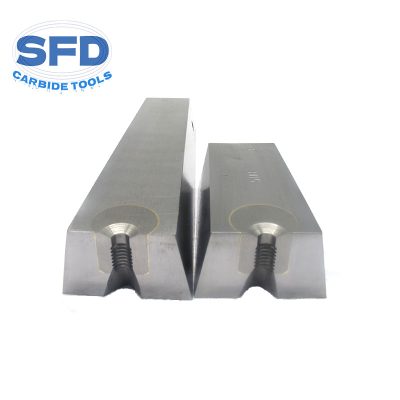

SFD can provide Roll ring and composite roll range from outer diameter 100 mm-550 mm, and thickness from 30mm-500mm. Roll rings’ grooves(and ribs) can be directly notched before shipping, which saves customers much production time and cost.

Grade Selection

In light of the variety of rolled steel products and the different characteristics of mill stands, selecting a correct carbide roll grade is the priority to optimize the mill condition.

Machining equipment

The machining equipment for the roll ring are CNC grinding machine and a WENDTGERMANY lathe with high precision, stability, and low failure rate which makes the quality of the final product a leading level.

After a certain period in the rolling groove, micro-cracks will gradually expand, elongate, and deepen. When the crack depth reaches approximately 0.2-0.4 mm, the rolls should be removed from the machine for grinding and maintenance. This crack depth is considered relatively safe, and the corresponding rolling reduction is typically within the following range (using a 6.5 mm wire rod as an example):

| Pre-finishing mill stands | 4000~8000tons |

| Finishing mill 1~2 stands | 3000~5000tons |

| Finishing mill 3~4 stands | 3000~5000tons |

| Finishing mill 5~6 stands | 1500~3000tons |

| Finishing mill 7~8 stands | 1500~3000tons |

| Finishing mill 9~10 stands | 500~2000tons |

According to the basic principle of high-speed steel mill rolling, each groove must be set with the proper milling amount for grinding. The roll then needs to be unloaded when it reaches the proper milling tonnage, and must not be overfilled. Otherwise, it may cause broken roll rings, and inconvenience for the next regrinding.

Marking & Sorting of the Grade

Each roll ring produced by Hengcheng will be laser marked with grade No. The grade must be identified and sorted out when the roll rings are notched and installed on the mill. The stands cannot be freely changed, otherwise, it will affect the usage of this roll ring and its neighboring ones.