From Resource Extraction to Innovative Manufacturing

Tungsten, the most critical component in cemented carbides, is an essential strategic resource. China is the world’s largest tungsten resource holder, accounting for about 58% of global reserves and supplying around 80% of the global tungsten metal demand, making it a metal with long-term implications for national security and economic development.

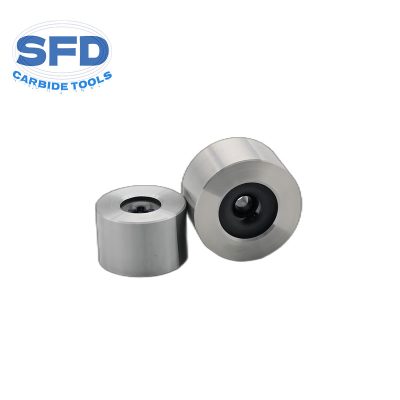

China’s cemented carbide industry has made significant strides by introducing advanced technologies and equipment, dramatically improving its process technology and equipment level. The industry now covers a wide range of applications, from metal cutting to mining, wire drawing dies, and wear-resistant parts, forming a complete industrial chain from tungsten resource extraction and smelting to powder preparation, cemented carbide production, and tool manufacturing.

Since the 21st century, China’s cemented carbide industry has embarked on a new phase of development. Enterprises have accelerated their consolidation and resource integration, with rapid growth in the private sector. Simultaneously, companies have been continuously upgrading their technologies, strengthening research and development, and adopting new technologies and equipment, leading to an expansion in production, optimization of the industry structure, improved profitability, and industrial upgrades.

Advancing Domestic Production of High-Tech Equipment for China’s Cemented Carbide Industry

A series of advanced equipment, including automated reduction furnaces, carburizing furnaces, tilting ball mills, stirred ball mills, spray drying towers, fully automatic presses, continuous vacuum sintering furnaces, gas pressure sintering furnaces, and coating furnaces, have gradually been localized and produced domestically, further enhancing the technological and equipment capabilities of the industry.

Unlocking the Potential of Tungsten Recycling: Driving China’s Green Economic Transformation

Currently, 12% of China’s tungsten raw material supply comes from recycled tungsten, while the remaining 88% is from primary tungsten ore. In comparison, advanced countries typically have a tungsten recycling rate of over 30%. The main tungsten scrap collection and distribution centers in China are located in Hebei, Hunan, and Jiangxi, with Hebei Qinghe County being one of the largest hubs for recycled cemented carbide and other rare metal scrap trading and regeneration.