A Wise Choice for Productivity Enhancement

In modern manufacturing, improving productivity is one of the key goals for businesses. In the nail-making industry, choosing the right nail-making machine is crucial for achieving efficient production. This article will compare high-speed nail making machines with conventional ones and present data comparisons to help you make an informed decision.

Enhanced Production Efficiency:

High-speed nail making machines utilize advanced technology and automated control systems, enabling them to complete nail-making tasks at a faster rate. In contrast, conventional nail making machines have relatively slower production speeds. According to actual data comparisons, high-speed nail making machines can increase production efficiency by over 30%, significantly saving production time and labor costs.

Precision and Consistency:

High-speed nail making machines achieve higher nail-making precision and consistency through precise control systems. This ensures precise positioning and angles for each nail, ensuring the stability and consistency of product quality. Conventional nail making machines, due to technological limitations, cannot achieve the same level of precision and consistency.

Cost Savings in Material Usage:

Due to precise control and optimized design, high-speed nail making machines minimize material waste. In contrast, conventional nail making machines may result in deviations in nail positioning or poor fixation, leading to increased material waste.

The following real-life case is based on the Chinese market for conventional nails with a diameter of 2.8mm and a length of 50mm. The waste rate for traditional machines is typically between 1.5% and 4%. The X100A high-speed nail making machine achieves a 100% qualification rate, saving RMB 27 per ton. In terms of producing the same quantity of nails, the X100A has a shorter operating time, saving electricity costs of approximately RMB 50-60 per ton. The internal lubrication system equipped in the X100A high-speed nail making machine eliminates oil stains on iron wire or nails, eliminating the need for polishing processes and saving approximately RMB 50 per ton. Additionally, the X100A machine recycles all lubricating oil, providing an additional saving of RMB 5 per ton.

Direct cost savings amount to approximately RMB 120-150 per ton. In the Chinese market, the profit margin for conventional loose nails is approximately RMB 50-150 per ton.

Ease of Operation:

High-speed nail making machines are typically equipped with intuitive user interfaces and user-friendly control systems, making operation more convenient. In contrast, conventional nail making machines may require longer learning and adaptation periods. The user-friendly operation of high-speed nail making machines greatly reduces operator training costs and reduces error rates during the production process.

Based on the data comparisons above, high-speed nail-making machines have significant advantages in enhancing production efficiency, ensuring nail-making precision, saving material costs, and simplifying operations. For businesses striving for efficient production, choosing a high-speed nail making machine is a wise decision.

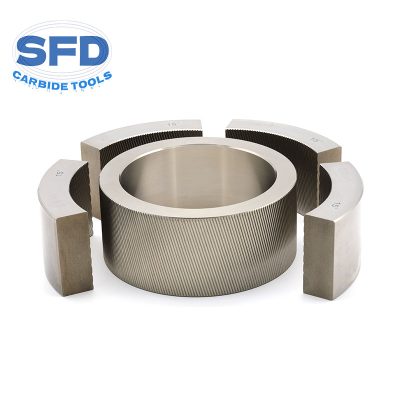

With 12 years of experience in the steel nail-making industry, SFD has established a stable customer base and a good reputation. Our core business is providing one-stop procurement of steel nail-making tools, and we also serve as agents for renowned domestic nail-making machine brands. We collaborate with these high-quality machine manufacturers to expand into the international market and contribute to efficient nail production. We understand that upgrading nail-making equipment means customers will reduce their purchases of conventional nail-making molds, due to the longer lifespan of high-speed Tungsten Carbide Nail Cutting Die, resulting in shorter procurement cycles. However, we are committed to using innovative technology upgrades to genuinely help customers reduce costs and increase efficiency, thereby gaining the trust of more customers.